3D Printed Crowns: The Future of Same-Day Dentistry

The Future of Dentistry is Here: A Look Inside Our Digital Lab

For many years, the process of getting a dental crown meant two or three separate appointments spread over several weeks. It was a lengthy process that required you to wear a temporary crown and wait patiently for a dental laboratory to create your final restoration. At Silver Oaks Dental Clinic, we are changing that experience entirely. We believe the future of dentistry is here and that it should be defined by speed, precision, and comfort. A major part of this revolution is the advent of 3D printed crowns.

We are proud to share that our practice has just installed brand-new SprintRay 3D printers, making us among the first in South Africa and the very first in KwaZulu-Natal to offer this state-of-the-art technology. These machines allow us to design and create crowns, veneers, fillings and more, all on-site and often on the same day. For our patients, this means a dental experience that is faster, more precise, affordable and more convenient than ever before.

SprintRay 3D Machinery

What are 3D Printed Crowns?

A 3D printed crown is a superior-quality, permanent dental restoration that a digital printer creates from a ceramic resin material. Unlike a crown made in a traditional lab, which an artisan hand-crafts or a milling machine carves, a 3D printer builds the crown layer by layer, based on a precise digital design.

This process is a key component of what we call modern Digital Dentistry. It is a complete workflow that uses computers and advanced software to make dental treatments easier, quicker cheaper, and far more accurate.

From Digital Scan to Perfect Fit: The 3D Printing Process

The journey of a 3D printed crown is a testament to the incredible advancements in dental technology. It begins the moment you sit in the dental chair and ends with you walking out with your final smile.

Step 1: The Digital Impression

Gone are the days of messy, uncomfortable impression trays. Our process begins with an intraoral scanner, a small, wand-like device that we move around your mouth. It captures thousands of digital photographs to create a highly accurate, three-dimensional digital model of your teeth and gums. This part of the process is quick, comfortable, and a huge relief for patients who have sensitive gag reflexes.

Step 2: Designing Your Crown

Once we have a digital model of your mouth, we use advanced CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) software to design your new crown. Our experienced dental professionals can digitally sculpt the crown, ensuring it fits perfectly into your bite and matches the shape and size of your other teeth. We can even select the ideal colour to ensure it blends seamlessly with your natural smile.

Step 3: The 3D Printing

The digital design is then sent to our on-site 3D printer. The printer takes a resin base and precisely builds the crown, layer by layer, according to the digital blueprint. The process is remarkably fast, and you can watch it happen right here at the clinic. The materials we use are regarded as best in class worldwide, ensuring your final restoration is not only beautiful but also durable and biocompatible. Our Resins are all approved by the FDA and the CE.

Step 4: The Final Touches

After the crown is printed, our team carefully removes it from the printer and puts it through a post-processing stage. This involves cleaning and curing the material to ensure maximum strength and a smooth finish. We then expertly bond the final restoration to your tooth, and you are ready to go. The entire process is a seamless example of how innovation helps us care for you better.

Why Our 3D Printers Benefit You

At Silver Oaks Dental Clinic, we invest in technology because it allows us to offer you a better experience. Our new 3D printers provide tangible benefits that you will notice and appreciate.

Unmatched Precision and Comfort

The digital impression process is far more precise than a traditional impression. This accuracy translates directly to a better-fitting restoration, which can reduce the need for adjustments and increase the lifespan of your crown.

Efficiency and Speed

The ability to produce a crown on-site means no more waiting for a lab. You can walk in for a scheduled treatment and leave with your final smile the very same day. This is a huge advantage for those with busy schedules.

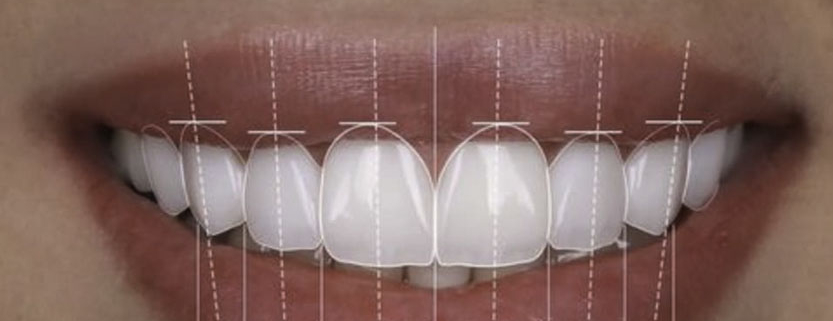

Exceptional Aesthetics

The advanced materials and precise digital design allow us to create a restoration that matches the colour, shape, and translucency of your natural teeth. The result is a crown that is virtually indistinguishable from your other teeth.

Beyond Crowns: What Else Can Our 3D Printers Create?

While 3D printed crowns are a flagship benefit, our new technology is incredibly versatile. It allows us to produce a range of other restorations with the same level of speed and precision, including:

- Dental Veneers: For minor cosmetic corrections.

- Surgical Guides: For more precise and safer placement of [dental implants] (link to Dental Implants page).

- Inlays and Onlays: For repairing smaller areas of tooth decay.

- Custom Appliances: Like night guards or retainers, with greater speed and accuracy.

How Silver Oaks Dental Clinic Leads the Way

This new technology represents a huge leap forward in dentistry, and we are thrilled to be leading the way in KwaZulu-Natal. Our investment in the SprintRay Pro 2 and the SprintRay Midas printers demonstrates our commitment to innovation and patient care. At Silver Oaks, innovation is never about the equipment alone. It is about how it helps us care for you better. With this investment, your smile is in the future already.

To learn more about how we use technology to enhance your dental care, or to schedule a consultation, please contact us today.

FAQs: Your Questions About 3D Printed Crowns

- Are 3D printed crowns safe? Yes, they are completely safe. We use biocompatible and medically approved materials for all of our 3D printed restorations. The materials are strong, durable, and pose no health risks.

- How long do 3D printed crowns last? You can expect a 3D printed crown to last as long as a traditional crown. With proper care and oral hygiene, they can serve you well for many years. The longevity of any restoration depends on your daily habits and regular dental check-ups.

- Are 3D printed crowns more expensive? The cost of a 3D printed crown is generally cheaper than a traditionally made one due to the lower lab costs. While the technology is advanced, the efficiency of our on-site lab reduces overheads. This allows us to provide you with a high-quality, same-day service without a premium price tag.

- How can a 3D printer create a crown that fits me perfectly? The process begins with an incredibly accurate digital scan of your mouth. Our sophisticated design software then uses this scan to create a virtual crown that fits your bite and tooth shape with absolute micron precision. The 3D printer then builds this exact design.

- Can a 3D printer create a full set of teeth? While our 3D printers are capable of creating multiple crowns or veneers for a patient, a full set of teeth or a full denture still requires a comprehensive, multi-step process. Saying that, with the right planning and design beforehand we are often able to do a full arch on the same day.

Leave a Reply

Want to join the discussion?Feel free to contribute!